In today’s rapidly evolving energy landscape, modernising infrastructure is crucial for ensuring a reliable electricity supply. Companies like GMC Utilities Group are at the forefront, tackling major projects such as the Greenlink Interconnector. In this blog, we explore how SNG contributed to this ambitious endeavour by supplying specialised rope solutions critical for offshore cable installation.

What is the Greenlink Interconnector Project?

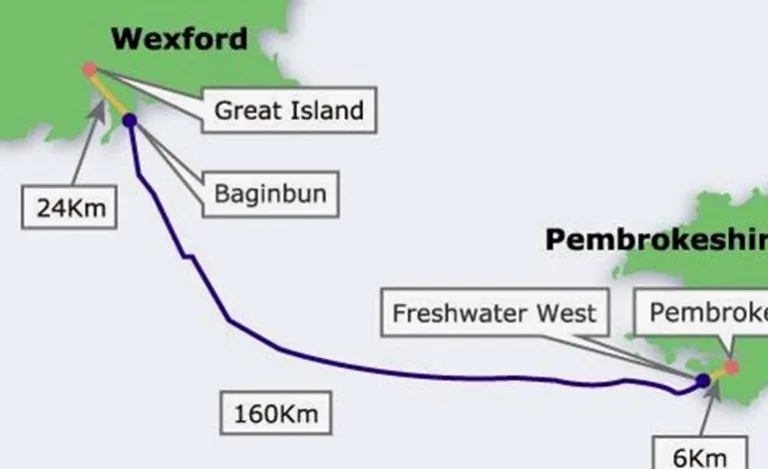

The Greenlink Interconnector is a ground-breaking initiative designed to connect the electricity grids of Ireland and Great Britain. It aims to enhance energy security, support renewable energy deployment, and improve market integration. Here are some key details:

- Length: Over 160 kilometres of high-voltage direct current (HVDC) cables.

- Depth: Installation depths of 60 to 120 meters beneath the Irish Sea.

- Purpose: Enable the bi-directional flow of electricity, allowing for optimised energy resource utilisation.

The Challenge: Unique Rope Requirements

GMC Utilities faced several challenges in this project, primarily concerning the supply of non-standard, high-strength ropes crucial for their cable-laying operations. The specific requirements included:

- Custom Length and Break Load: GMC needed 300 kilometres of 12mm polypropylene rope, with a minimum breaking load of 2.21 tonnes to ensure safety and reliability during installation.

- Durable Reels: The ropes required packaging on wooden reels to shield them from harsh underwater conditions, ensuring they remained tangle-free during deployment and retrieval.

Why SNG Was the Ideal Partner

1.Strong Supply Chain Relationships

SNG has developed strong partnerships with manufacturing facilities, enabling them to respond swiftly to specialised requests. When GMC reached out for assistance, SNG was ready to mobilise their resources effectively.

2.Custom Solutions for Complex Needs

SNG’s commitment to custom solutions allowed them to meet GMC’s exact specifications, ensuring that the ropes produced were both reliable and resilient under challenging conditions.

3.Proven Track Record

With years of experience supplying high-quality products for the energy sector, SNG demonstrated an ability to overcome logistics and production challenges, ensuring timely delivery without compromising on quality.

SNG’s Approach: Swift Production and Delivery

Upon receiving GMC’s requirements, SNG took immediate action:

- Resource Reallocation: Halted the production of other items to prioritise GMC’s order.

- Continuous Production Schedule: Maintained a 24/7 operation for two weeks to complete the manufacturing of 300 1,000-meter coils.

- Efficient Logistics: Packaged the coils securely in containers and shipped them promptly to Ireland.

Successful Outcomes

The collaboration yielded remarkable results:

- On-Time Delivery: All ropes were delivered within the required timeframe, allowing GMC to maintain project schedules.

- Operational Success: The high-strength ropes were successfully utilised in pulling the HVDC cables without any incidents.

- Material Integrity: The wooden reels held up well under the demanding conditions of the project.

SNG’s Future in the Energy Sector

As the energy sector continues to evolve, SNG’s dedication to innovation and specialised solutions places them at the forefront of supporting new energy projects. Their contributions in projects like the Greenlink Interconnector are vital for achieving sustainability goals not only in Ireland but globally.

The Bigger Picture: Supporting Ireland’s Green Energy Goals

The Greenlink Interconnector Project is more than just an infrastructure improvement. It is a critical component of Ireland’s broader strategy to transition to cleaner energy sources. With more reliance on renewables, efficient energy flows between regions will facilitate greater energy security and a reduction in greenhouse gas emissions.

Takeaways from the Project

- Custom Solutions: Tailoring products to meet specific project needs can make a significant difference.

- Collaborative Partnerships: Building strong relationships with suppliers and partners ensures better project outcomes and enhanced operational efficiency.

- Importance of Timely Delivery: Adhering to deadlines is crucial for the success of large infrastructure projects, reinforcing the necessity for agile partners.

As energy demands continue to grow, partnerships between innovative companies like SNG and GMC will be vital in transforming infrastructure and promoting sustainability in the energy sector.